16 Jun,2025

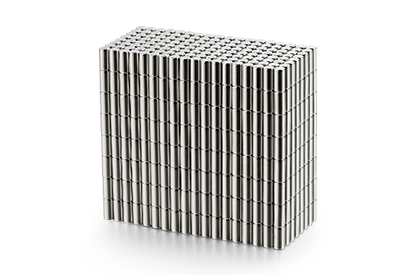

Rising Demand for Rectangular Neodymium Magnets Signals Market Expansion in Precision Applications

In recent years, Rectangular Neodymium Magnets have witnessed a significant surge in demand across various industries, driven by their exceptional magnetic properties and versatile design. As the global push toward miniaturization, energy efficiency, and high-performance technology intensifies, these magnets are emerging as a cornerstone in next-generation engineering and manufacturing solutions.

Rectangular Neodymium Magnets are a specific shape of rare-earth magnet made from an alloy of neodymium, iron, and boron (NdFeB). Known for their incredible magnetic strength relative to size, these magnets are particularly valuable in applications where space is limited, but a strong magnetic field is essential. From compact motors and magnetic sensors to precision electronics and industrial automation, the rectangular shape offers designers a unique advantage in alignment, assembly, and integration.

One of the key drivers behind the growth of the Rectangular Neodymium Magnets market is the expanding electronics and electric vehicle (EV) sectors. As motors used in EVs and high-efficiency appliances demand powerful yet compact magnets, the rectangular form factor provides optimized surface contact and directional magnetism that enhance performance. Moreover, these magnets are commonly used in robotics, aerospace components, and medical instruments, where high magnetic flux and geometric precision are critical.

Industry experts report that advancements in magnet coating technologies—such as triple-layer nickel-copper-nickel or epoxy coatings—are further expanding the usability of Rectangular Neodymium Magnets in harsh or corrosive environments. This protective innovation makes them ideal for outdoor devices, underwater tools, and machinery exposed to extreme conditions.

In addition to industrial applications, consumer products such as smartphone accessories, magnetic tools, and even DIY crafts are incorporating rectangular neodymium magnets for their compact power. Their ability to securely fasten components without bulky hardware offers aesthetic and practical benefits across product categories.

According to market analysts, Asia-Pacific remains the largest producer and consumer of Rectangular Neodymium Magnets, with China playing a dominant role in raw material extraction and magnet fabrication. However, increasing environmental regulations and resource concerns are prompting manufacturers in Europe and North America to invest in sustainable sourcing and recycling technologies.

Looking ahead, the demand for energy-efficient devices and green technologies will likely continue to boost the adoption of Rectangular Neodymium Magnets. As industries seek to balance performance, size, and sustainability, these small but powerful components are set to play an even larger role in global innovation.